Quality, Health, Safety and Environment

Pakistan Petroleum Limited (PPL) recognizes that operational safety and health for staff and contractors, maintaining quality of processes and outputs and constricting the ecological footprint of operations promotes excellence and corporate responsibility.

Pakistan Petroleum Limited (PPL) recognizes that operational safety and health for staff and contractors, maintaining quality of processes and outputs and constricting the ecological footprint of operations promotes excellence and corporate responsibility.

Quality, Health, Safety and Environment (QHSE) Dept. was established to provide integrated support for assurance and control of technical and administrative operations, works performance, asset integrity, process safety besides, inculcating safety awareness and adopting best operational practices in strict compliance with statutory Health, Safety and Environment standards.

The department assists management in defining company’s QHSE Policy which plays a key role in its decision-making process to ensure compliance with relevant legislations and to achieve continual improvement. In addition, the department has classified Smoking & Seat Belt Policies in pursuance to establish safe working practices for its employees and visitors.

The department is also responsible for institutionalizing QHSE, providing professional observations and advice where needed, without assuming the executing department’s operational role. For this, the department has structured QHSE Management System (QHSE MS) to satisfy the needs of its customers, employees, all the shareholders and the community at large to continuously improve performance of PPL in the areas of Quality, Occupational Health, Safety and Environment (QHSE). The QHSE MS is consistent with the requirements of the following recognized international standards:

• ISO 9001

• ISO 14001

• ISO 45001 (Previously OHSAS 18001)

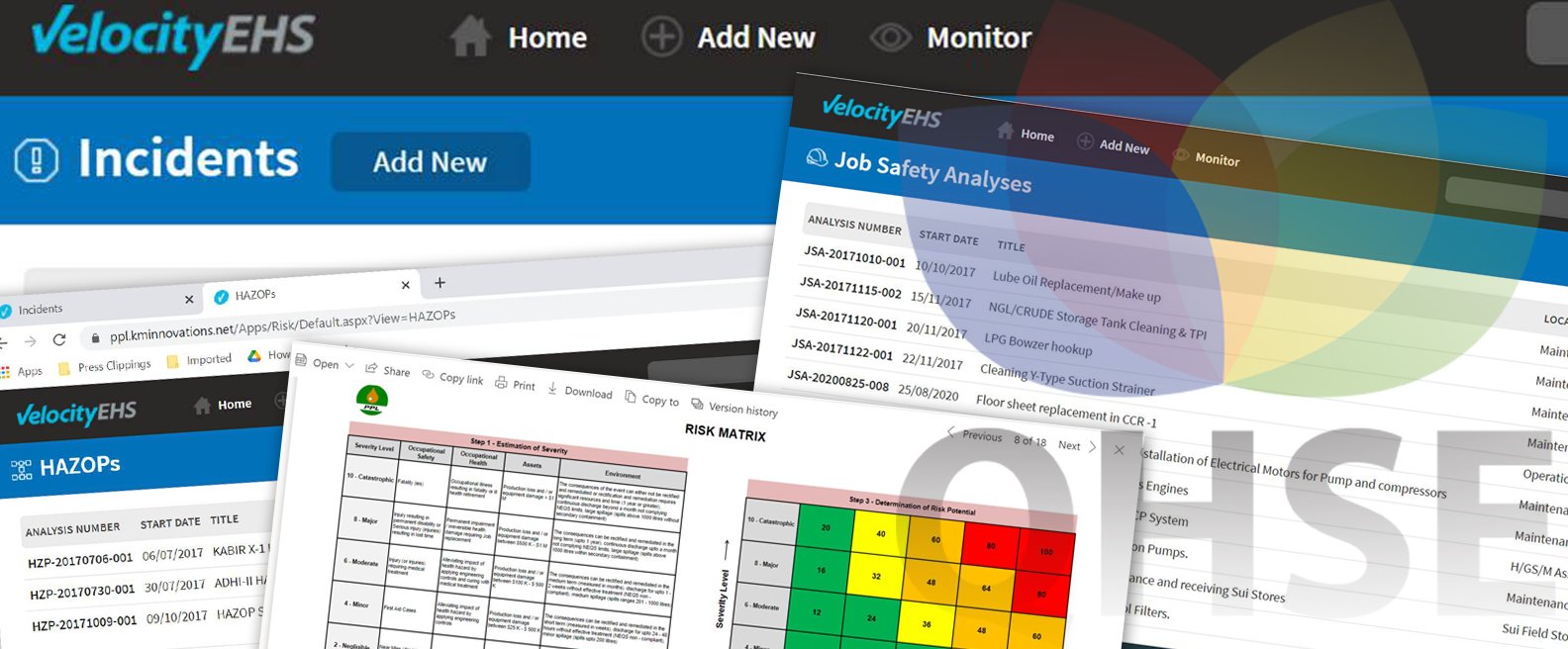

For consistency in implementation of standard QHSE practices, staff capacity building sessions on emergency response, asset integrity and process safety are regularly held. Moreover, safety guidelines are provided to staff, contractors and guests visiting fields and office locations. QHSE practices and tools are integrated into management and operational processes, including software-based system is in place to report all type of incidents, record investigation where necessary and related corrective actions. The system is also being used to record all audits & inspections, record corrective actions and track close out. Provision of Job Hazard Analyses records on the system is facilitating entire organization to apply experiences of various locations. to obtain tangible benefits.

In pursuance of the Pakistan Environment Protection Act 1997, the department undertakes Initial Environmental Examinations and Environmental Impact Assessments for development projects followed by regular monitoring of project activities.

As a result, 12 assets and facilities are certified for ISO 14001 Environmental Management System (EMS) and 16 for ISO 9001 Quality Management System (QMS) and 14 for OHSAS 18001 / ISO 45001 Occupational Health and Safety Management System (OHS).

To sustain and update compliances, all certified facilities and departments undergo regular internal and external surveillance audits, following which corrective measures are implemented, if required. Employees from various technical departments are qualified lead auditors for ISO 9001 QMS, ISO 14001 EMS and OHSAS 18001 / ISO 45001 to assist in executing audits.

Workshops and trainings to raise QHSE & Process Safety awareness to build staff capacity are arranged at fields and head office.